Innovative industry applications for highest quality demands

National Welding is unique in its ability to meet the complex demands of heavy constructions welding and field service installations. For more than 22 years we’ve provided welding and welding management operations you need to keep your project moving forward.

Infrastructure

National Welding is unique in its ability to meet the complex demands of high production field welding and tunnel liner installation for general infrastructure construction and maintenance. For more than 22 years we’ve provided the welding and welding management you need to keep your project moving forward.

Hydro-electric

Hydro-electric power plants and penstocks often present obstacles such as steep pipe slopes, complex miter cuts, critical quality compliance rules, and extremely tight schedules. When you’re facing an uphill battle, trust the experience of National Welding.

Special Projects

Precision steel demolition, extremely high volume out-of-position welding, and access restrictions requiring specialized equipment are all considered “Special” projects. National Welding has the capability to design, build, and implement a specialized solution for you.

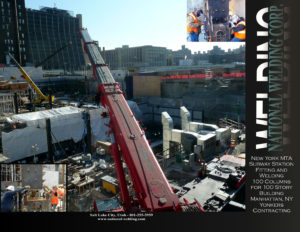

Heavy Construction

Large, heavy welded steel members are built in a shop with controlled, fixed equipment. Moving and welding these pieces in the field is not as simple. National Welding relies on time-tested equipment and manpower to safely and efficiently complete the largest of projects.

Pipelines

Welded steel pipelines have been around for years due to their reliability and versatility. Steel pipelines have the unparalleled ability to be cut, fit, welded, and sub-assembled in the field when exact dimensions are difficult to anticipate. Also, welded joints can be utilized to achieve up to 100% joint efficiency. This means that, from a design perspective, certain welded pipe joints can be considered equally as strong as the pipe itself.

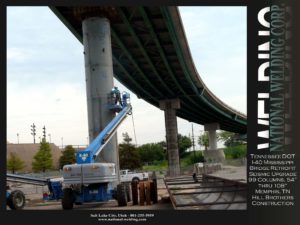

Bridges

Aging infrastructure and evolving code and safety requirements have necessitated an increase in structural upgrade requirements. Bridges and elevated structures are an area that has been particularly in the spotlight because a seismic event could have devastating consequences on a bridge that was not designed to withstand. Welded steel casings provide a simple and effective solution for seismic upgrading columnar structures. The steel can be cut and rolled into shapes and sizes that are easy to transport and install. They can then be installed and welded in the field and filled with structural grout providing a much stronger and more flexible column.

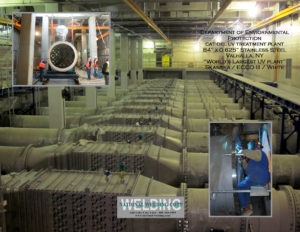

Water Treatment Facilities

Water treatment facilities differ from welded pipelines in that they generally involve an extremely high concentration of work on a relatively small area. National welding has welded many water treatment facilities and understands the importance of working with other contractors and promoting a team player attitude on the job site. National has even developed specialized welding equipment that is easily moved around the plant site and required minimal space to operate.

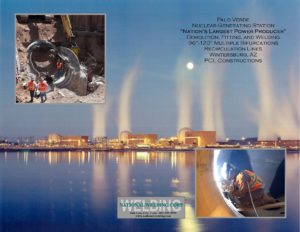

Power Plants

Welded steel components at power plants require highly skilled and highly qualified welding operators. Background checks and daily security clearance checks for all equipment and personnel often make staffing and managing power plant projects more difficult than other projects. National Welding has experience working in government restricted and is highly capable of navigating the obstacles that are associated with this type of work.

Penstocks

Penstocks, like pipelines, generally consist of large steel barrel spiral welded or plate fabricated pipe. The difference between the two often lies in the surrounding terrain. Because penstocks are a channel or pipeline for conveying water to a hydroelectric or power generation system, they often lie in steep and hard to access positions. Steep slopes in a penstock are a safety concern that should not be taken lightly.

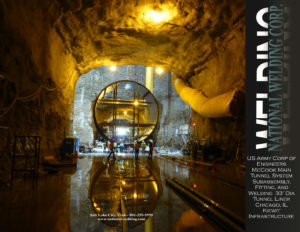

Tunnel Installation

Tunnel Liner installation is separated from open-cut pipe laying operations by the fact that the hydraulic excavators typically used in pipe trenching and laying will not work in the limited spaces of a tunnel. Because of these restrictions, tunnel pipe installations require heavy hydraulic and pneumatic equipment custom build to accommodate the pipe and tunnel size and taking into consideration the pipe weight and the annulus restrictions.

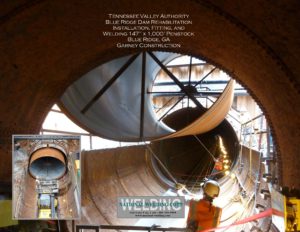

Dam Rehabilitation

Aging infrastructure coupled with increased water and power usage have created difficult situations when it comes to dam upkeep and repair. Dams and reservoirs often cannot be shutoff or drained for long durations because of excess lake water, downstream water demands, or recreational usage. The solutions that many owners turn to in this situation is the installation of a steel liner. These liners can be complicated shapes and sizes to match specific gate chamber dimensions as well as simple rolled steel liner installed an existing conduit. No matter the configuration, all dam rehabilitation projects share the same problematic characteristics: They involve working with tight quarters, strict seasonal schedules, and extreme safety requirements.

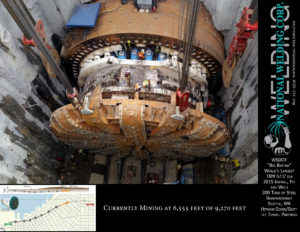

Piling, Casing, and Shoring

Many steel construction installation techniques involve mechanically pressing, pulling, or hammering material into the earth. These structures have different uses such as supporting large structures with foundation piling, conveying utilities through casing pipe, or ensuring safe and efficient work using sheet or secant piling. They have many different characteristics but the few they have in common are this: They are always on the critical path and they are very difficult to schedule due to unforeseen ground conditions. When hiring a welding company for this type of work it is important to consider their manpower and flexibility to accommodate changing schedules.