OSHA Part 1926, Subpart S; the industry recognized control document for confined space activity of underground tunnels, shafts, chambers and passageways. This section also applies to cut-and cover excavations which create conditions characteristic of underground construction (such as pipelines).

A confined space in this application is generally defined as a space that:

Is large enough for an employee to enter fully and perform assigned work;

Is not designed for continuous occupancy by the employee; and

Has a limited or restricted means of entry or exit.

Hazards that can exist in a pipeline include the following:

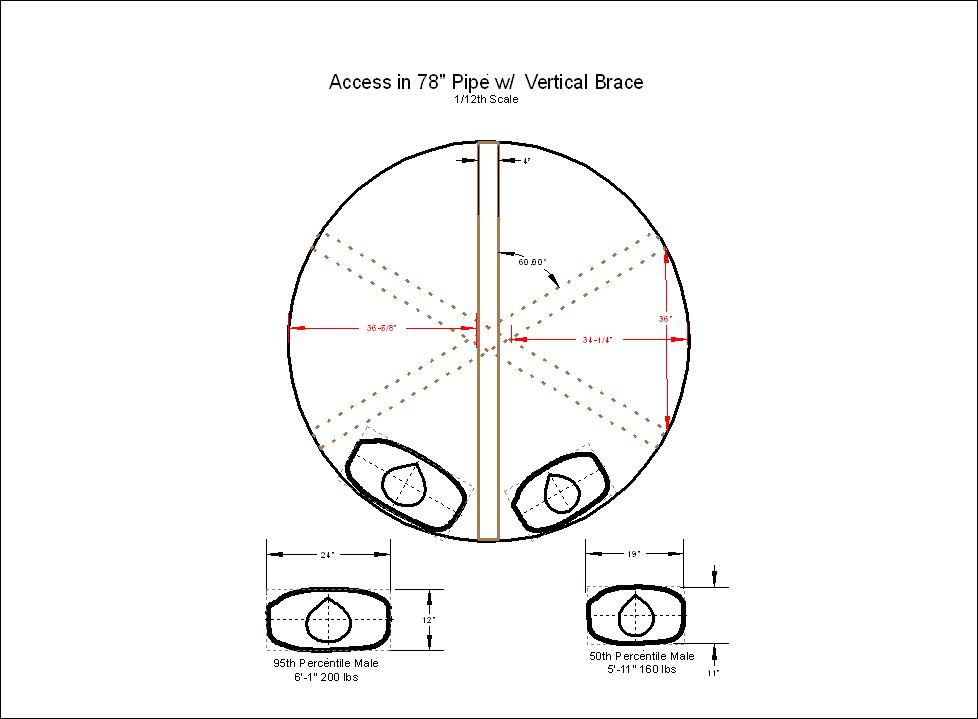

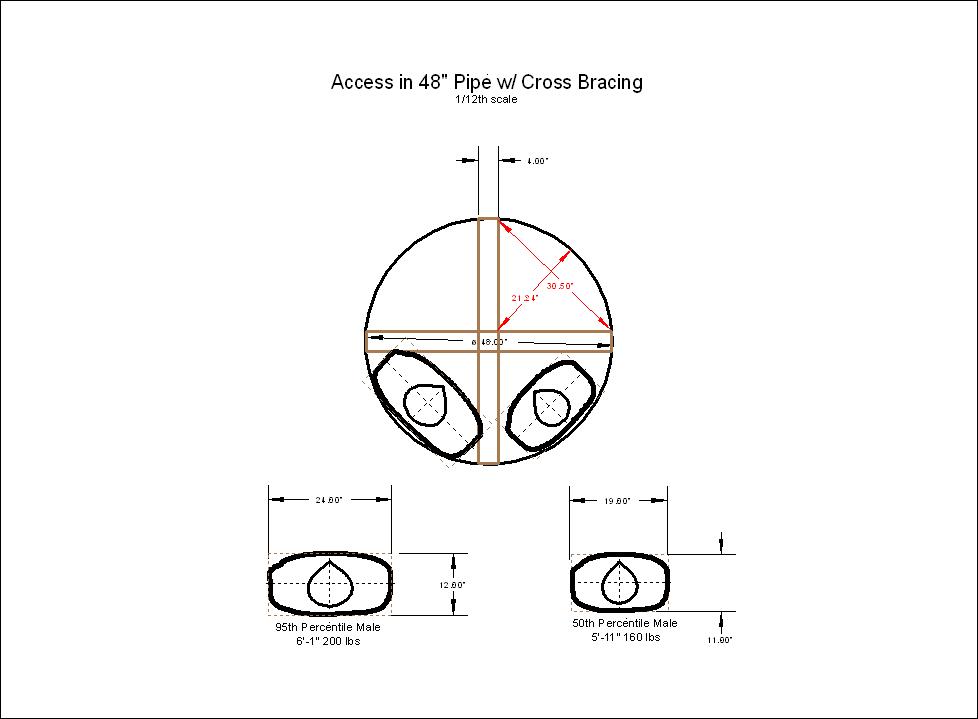

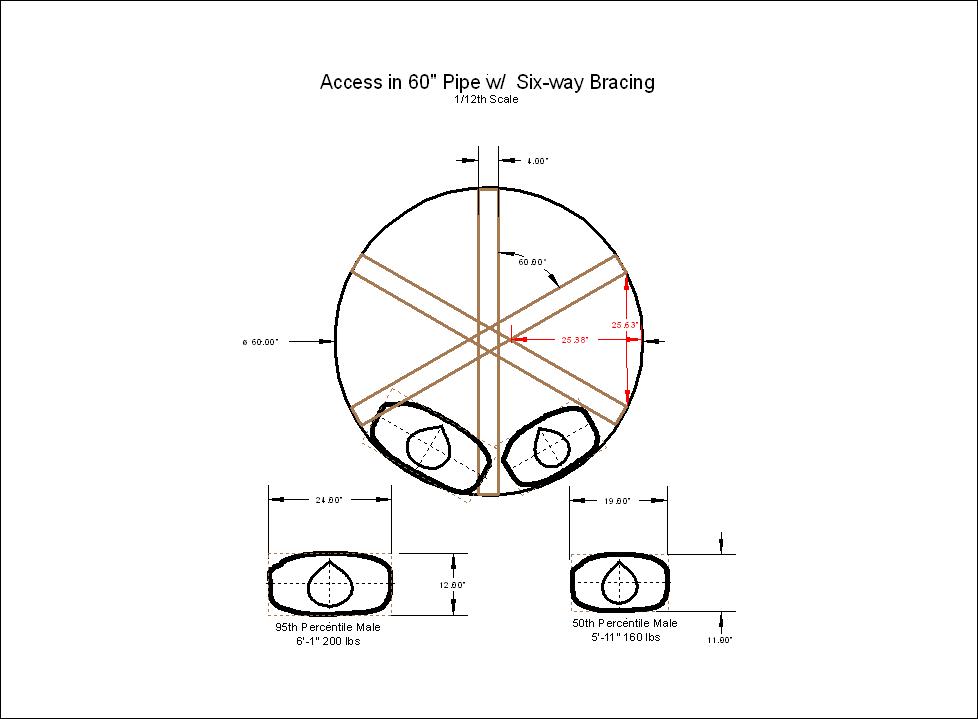

- Access/ Egress obstacles such as valves or bracing

- Distance between manways may present a long walk to the nearest exit

- Air quality changes due to adjacent construction operations

- Bad air quality due to pipe media or algae growth

All National Welding employees are trained in confined space entry as well as the usage of confined space monitoring and ventilating equipment. National Welding also owns and maintains a fleet of confined space equipment including portable ventilation blowers, single rider diesel access vehicles and multi rider electric vehicles. The combination of this equipment allows National to ensure the pipeline is properly ventilated and easily accessible to help ensure safe working conditions. The pictures below show the access/egress restrictions presented by bracing in pipes of various diameters as well as some examples of National’s access and ventilation equipment.

Image Gallery: